TECHNICAL BULLETIN NO. TB-FL01110

Use CO Measurement & Tune-Ups to Lower Fuel Costs

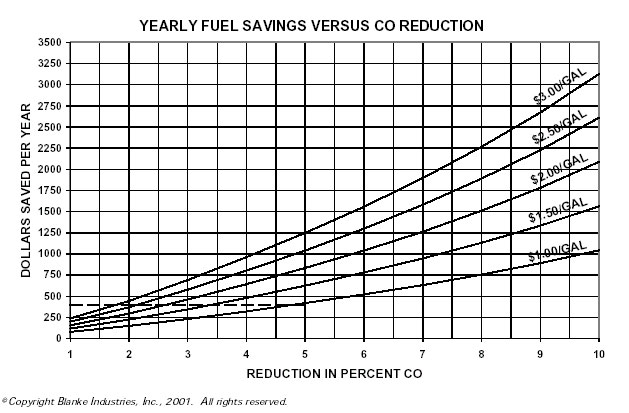

CO emissions are not only a health and safety issue, measuring them can be a tool for controlling fuel costs. Any CO above 0.5% at idle, cruise (governed throttle) and full load indicates wasted fuel. At 5% CO, a forklift can be wasting between $415 to $1,250 of fuel per year. Ten forklifts averaging 5% CO, will waste $4,150 to $12,500 per year, a significant amount. Traditionally, over half the forklifts tested are above 5% CO and occasionally they are above 10%. A forklift wastes 3% to 5% of its fuel for each 1% CO above this 0.5% CO target.

To get a good CO profile of the forklift, testing should be done at three different operating conditions. The first test is the CO at idle. The second test is the CO at cruise. And, the third CO test is done at full load. The averaged results of these three tests will give a reasonably accurate CO and fuel usage profile of a forklift.

After these are measured, the next step is to determine the average of these three CO readings. For example, if…

Step 1 Determine Idle CO = 4.8%,

Step 2 Determine Cruise CO = 5.2% and

Step 3 Determine Loaded CO = 6.5%, then

Step 4 Print Average CO = 5.5%

After a tune-up and carburetor adjustment, the average CO readings should be about 0.5% CO. In this example, the difference between the average CO readings before and after a tune-up, 5.5% minus 0.5%, is 5.0%, equaling a fuel savings of about 20%. The fuel dollars saved per year, for one forklift running on one shift for various fuel costs are shown in the graph below. Using this example, a forklift with CO lowered from 5.5% CO to 0.5% CO and fuel costing between $1/gal to $3/gal will save between $415 to $1,250 per year. Both CO emissions and fuel costs are reduced.

The total gallons a fleet wastes is the sum of gallons from each forklift multiplied by the number of shifts each works. The annual dollar amount is the total wasted gallons times the cost of fuel.